Cutting-Edge Technology

With experts across underwater robotics, electronics, control, hydrodynamics, software, and mechanical design, these multi-discipline engineers and technicians are finding ways to make your projects quicker, safer and cleaner.

Remote and Autonomous Underwater

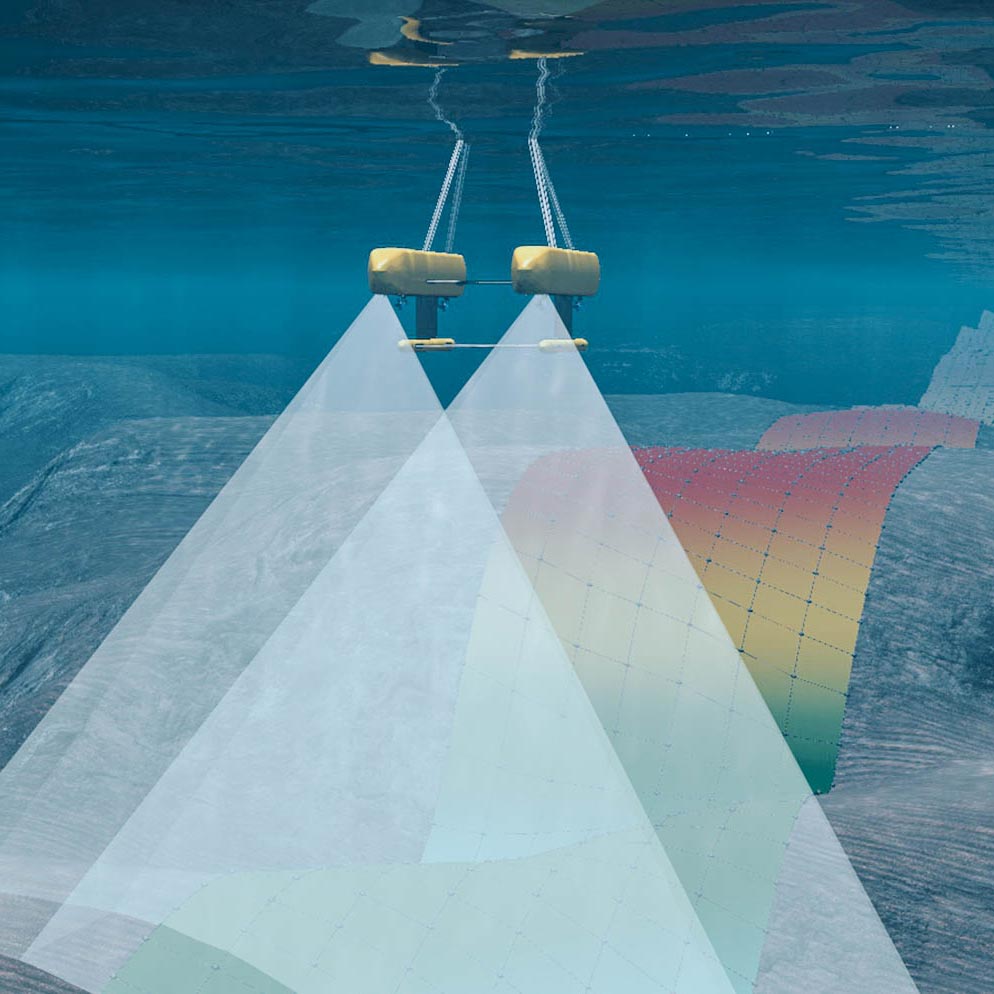

Inspection and Surveying

Embracing Industry 4.0 principles, MCS Group’s Ocean Aurora and AutoSpector advances the efficiency and sustainability of underwater operations resulting in significant cost savings and scheduling flexibility.

Our Ocean Aurora – Remote Survey Vessel (RSV) redefines subsea inspection and survey by eliminating the need for manned surface vessels. Equipped with either of our proprietary MiniSpector® and ProSpector® tethered ROVs, it enhances efficiency and accuracy in operations.

The AutoSpector – Autonomous Inspection Vehicle (AIV), tetherless and battery operated it allows for fully autonomous seabed inspection operations to be conducted from shallow to ultra deep water depth and can be deployed from Ocean Aurora RSV or independently.

All remote and autonomous underwater inspection and survey operations are managed from a dedicated onshore Remote Operations Centre (ROC). The ROC provides for skilled marine, inspection and vehicle operating crew to manage the full array of operations.

Digital Twin and 3D Measurements for Enhancing Subsea Operations

Our digital solutions, including Photo Realistic 3D Cloud (PRC) for precise subsea measurements and our Digital Virtuoso Asset Integrity Data Management System, provide comprehensive real-time data insights that enable proactive decision-making and targeted intervention.

Through this innovative approach, which embrace digital twin technology, empower clients with enhanced efficiency, reduced project duration, and improved cost-effectiveness.

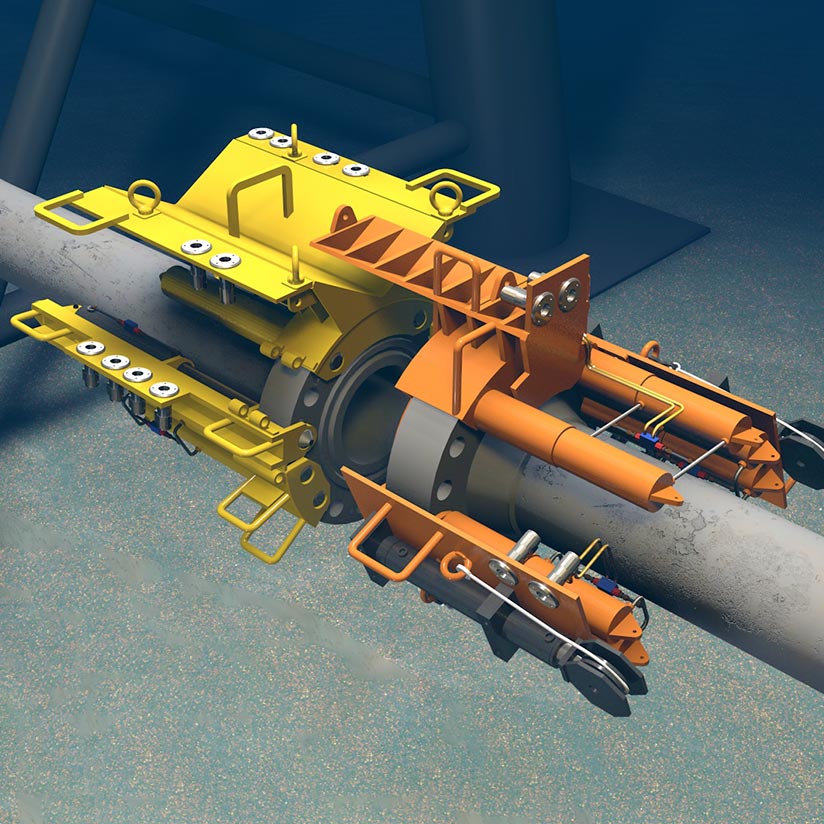

Pipeline and Diver-less Tie-Ins Technologies

Our patented Modular Pipelay System (MPS®) allows for the delivery of a weld-free, semi-autonomous subsea pipelay process that is faster, stronger, and cleaner than traditional pipelay methods. We utilize mechanical interference fit connectors for efficient pipelay and partner with NOV-Tuboscope to deliver Zap-Lok™ mechanical connectors globally.

The Stinger Deployed Diverless Connector (SDDC) allows for the diverless connection of flexible pipelines to rigid pipelines in shallow and deepwater environments. Based around proven hub connection systems and fully ROV operable the SDDC provides a very cost effective pipeline tie-in solution.

Our latest driverless pipeline tie-in technology development, Dexter- AI and remote ROV manipulator system to tie-in standard industry ANSI flanges uses robotic control and virtual reality for pipeline tie-ins. This system is operated with two ROVs from a DP vessel, reducing costs and risks while improving operational efficiency.

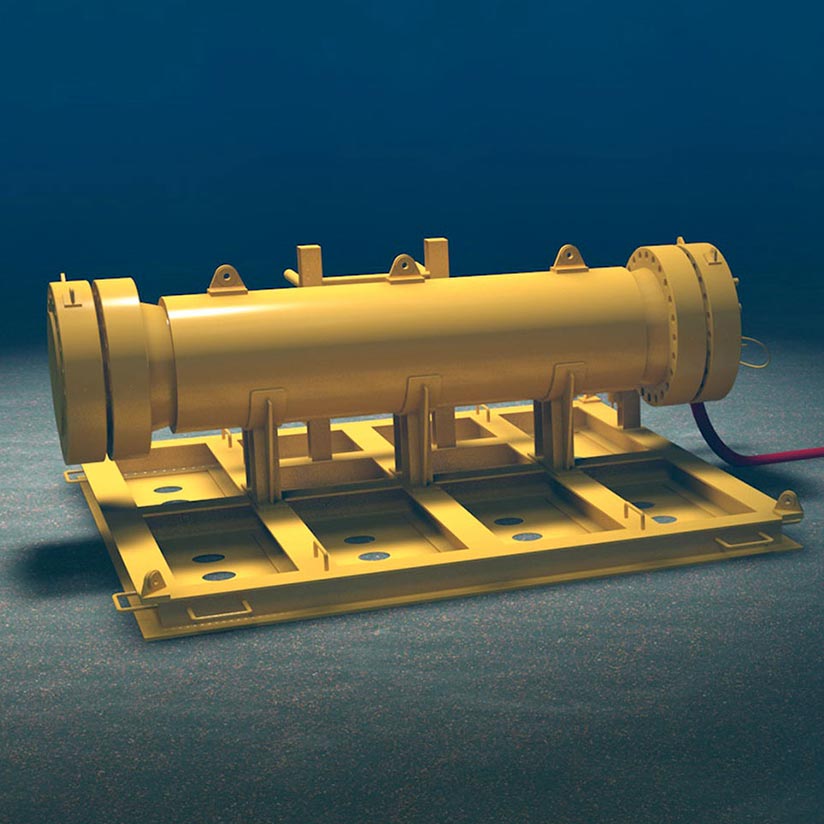

Technology Development

Our SubCell Subsea Battery System can provide back-up power to a subsea production system to reduce downtime caused by power outages. It consists of modular lithium industrial batteries, housed in a mechanical enclosure, for a safe and proven deep-water battery solution. The system is recharged from the surface and can power-up subsea components up to 30 days.

- A reliable and cost-effective underwater power system.

- Contributing to the electrification of the energy industry.

- Can withstand extreme conditions.